We manufacture desilting equipment and industrial suction engineering systems with worldclass standards

Mexican solutions in desilting, suction, and industrial cleaning with more than 27 years of experience. Reliable, safe, and innovative equipment.

OUR PRODUCTS

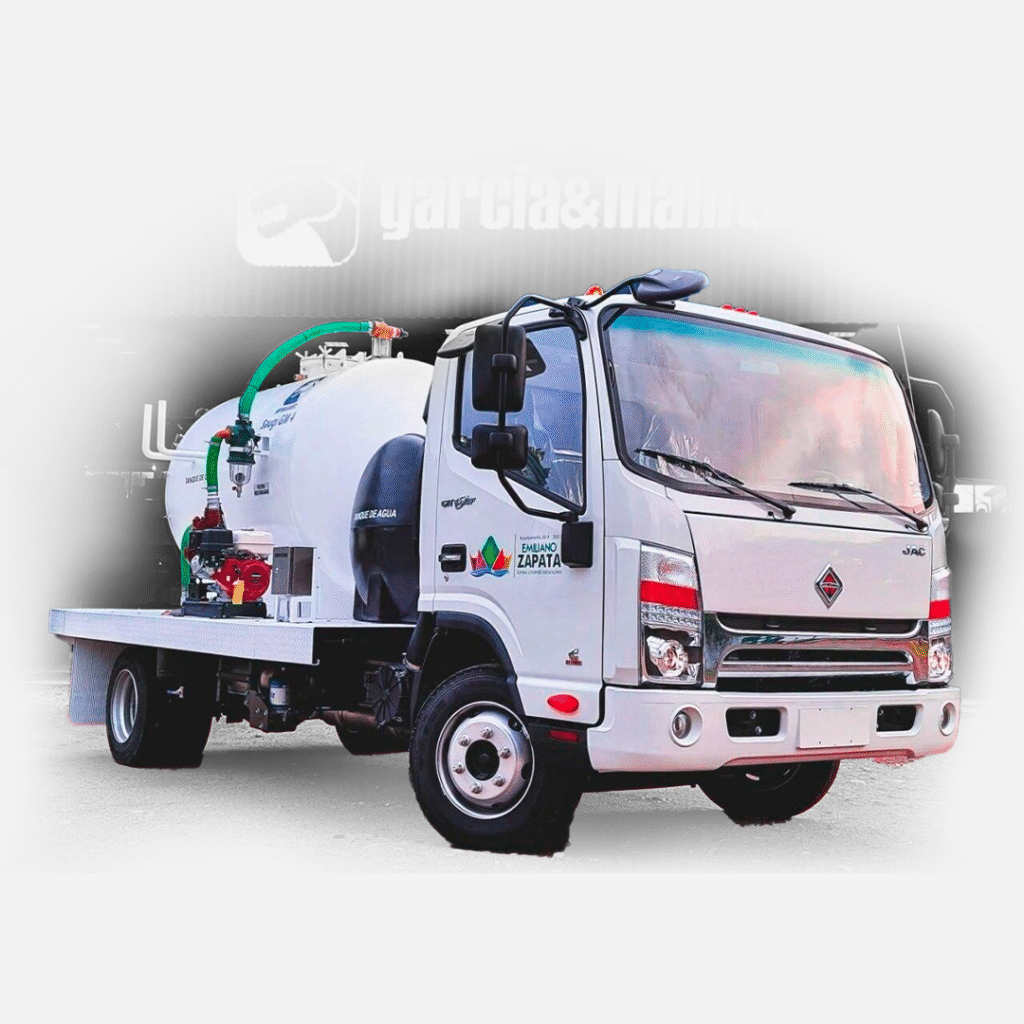

Combined desilting units

Designed to suction sludge, liquids, and heavy waste in pits, drains, and industrial plants. Ideal for municipal, sanitary, and environmental services.

- COMBINED DESILTING EQUIPMENT

Vasu-K Plus

- COMBINED DESILTING EQUIPMENT

Vasu-K

- COMBINED DESILTING EQUIPMENT

K-Sauger

OUR PRODUCTS

Water recycling and efficiency units

Sustainable technology to optimize water use during desilting. It allows recycling the extracted water and reducing operational consumption.

- WATER RECYCLING AND EFFICIENCY EQUIPMENT

Eco-Maestro

OUR PRODUCTS

High-pressure cleaning equipment

Compact solutions for cleaning pipes, hydraulic networks, and surfaces using high-pressure water. Ideal for preventive maintenance.

OUR PRODUCTS

Industrial suction equipment

Designed for heavy-duty suction of sludge, sediments, dust, or solid materials in industries, plants, and civil works.

- INDUSTRIAL SUCTION EQUIPMENT

Super-Sauger

- INDUSTRIAL SUCTION EQUIPMENT

Saugi

OUR PRODUCTS

Environmental emergency response equipment

Specialized equipment for suction and containment of hydrocarbon and chemical spills.

Accessories and Components

Essential add-ons to maximize the efficiency, safety, and performance of suction and desilting equipment.

Nozzles

For different pressure and flow applications.

Original Spare Parts

Certified components to maintain performance.

Plugs

Secure sealing during operations.

JUROP Vacuum Pumps

Power and reliability for continuous suction.

RIV Pressure and Vacuum Accessories

Industrial connectors, valves, and adapters.

Services

Preventive and corrective maintenance. Prevents downtime and extends service life.

Fast corrective support in the event of failures or unforeseen issues.

Original spare parts and functional verification after every intervention.

Technical support from specialists in desilting and operational safety.

Real results, more efficient operations

We bought a Vasu-K Plus for our fleet, and the difference was immediate: fewer stoppages, greater capacity, and consistent performance in difficult areas.

Ing. Raúl Méndez

Operations Manager

In an environmental emergency, the E-Sauger allowed us to contain and recover the spill in just a few hours; its power and ease of maneuverability helped us greatly.

María López

Environmental Coordinator

We’ve been working with García & Mallitz for more than two years, and their team has become a key partner in our operations. They are the best.

Ing. Rafael Morales

Maintenance Manager

We guide you in choosing the best solution

We guide you step by step to choose the right equipment configuration, tank capacity, pump type, accessories, and safety options.

Comparison of alternatives with pros and cons

Needs and priorities assessment

Clear technical and financial recommendation

Implementation and startup plan

Technical information on desilting and suction

How to choose a desilting truck?

To do so, the following information is required:

- Minimum and maximum drain diameter

- Maximum distance between manholes

- Distance to the landfill/dump/treatment plant

- Maximum manhole depth

- Percentage of sediment in the drain (%)

- Whether there is abundant water supply

- Whether there is an explosion risk

How many trucks does my organization need?

According to European standards, to clean 100% of the drainage network at least once a year, one desilting truck is needed for every 100 km of drainage.

What is the purpose of desilting drainage systems?

Desilting drainage and sewer systems is a vital process to extend their service life. It is carried out in order to:

• Remove sediments, incrustations, roots, grease blockages, and other elements to ensure hydraulic efficiency and prevent the formation of bad odors and gases caused by decomposition.

• Eliminate plugs or obstructions.

• Serve as a preliminary step before a video inspection and subsequent rehabilitation.

• Remove corrosive products, protruding pipes, and other artificial obstacles.

• Ventilate the pipes to prevent the formation of sulfuric and hydrogen sulfide gases, which cause premature deterioration of drainage systems.

• Extract sediment to prevent flooding.

• Ensure the designed service life of drainage systems.

What does the desilting process consist of?

A water pump injects a flow at a specific pressure and volume through a high-pressure hose, whose end is fitted with a nozzle.

This nozzle has orifices oriented at specific angles that allow it to move through the drain and perform mechanical tasks such as dragging sludge, removing roots, clearing grease blockages, cutting protruding pipes, dragging stones and mud, among others.The nozzle generates a reaction force that pulls the high-pressure hose forward against the direction of the drainage flow, from the starting manhole to the ending manhole. Then, using the hydraulic reel on which the hose is mounted, the hose is retrieved, and the water jet drags sludge, stones, and debris back toward the manhole.

The water jets coming from the nozzle accelerate the wastewater flow, loosening sediments, creating turbulence, and transporting them as suspended particles back to the initial manhole.

Once these sediments reach the manhole, they are suctioned into the sludge tank.

What are the main problems caused by poor maintenance of drainage and sewer systems?

- Formation of cracks, fractures, and subsequent street collapses

- Contamination of the groundwater table caused by wastewater leaks

- Rainwater infiltration into the drainage system

- Generation of bad odors

- Premature corrosion of cement/ceramic pipes

- Incrustations that reduce hydraulic capacity and create blockages

- Proliferation of bacteria and parasites

- Deterioration of cement/brick piping

- Reduced liquid-retention capacity in drainage systems during the rainy season, leading to flooding

What does the efficiency of my desilting truck depend on?

Efficiency depends on several factors, such as:

• The level of sediment in the drainage system

• The type of nozzles being used

• The diameter of the pipe to be desilted

• The depth of the manholes

• The distance between manholes

• The distance from the work site to the dump/treatment plant

• The sludge and water tank capacity

• The vacuum system used

• The capacity of the high-pressure water pump

• The operator’s training

• The planning of activities

Why are nozzles important?

Nozzles are the accessory that receives the least attention, yet they are the most important tool for desilting. Choosing the right nozzle helps increase the linear meters cleaned per unit, reduce fuel and water consumption, and prevent premature wear of engines and dynamic components. It also helps protect the physical integrity of the pipes. In other words, the correct high-quality nozzles allow you to recover your investment in a matter of months, solve problems on the first pass, and achieve more with less.

What types of sediments are found in drainage systems?

The sediments found in drainage systems consist mainly of:

• Mineral materials (sand, stones)

• Organic materials (food waste, paper, grease)

• Other materials (cans, bottles, plastics, debris)